dirty water drainage pump factory

Latest articles

When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreSeries of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreProcess speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreSlurry Pump Speed

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read More- Keeping clean catch basins clean from solids

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreApplications

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreSlurry Pump

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreMany types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreDetermine the operating parameters of the pump.

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

dirty water drainage pump factory...

dirty water drainage pump factory 【dirty water drainage pump factory】

Read More

Popular articles

- Determine the nature of the material to be pumped

- Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

- Monitoring

- Includes a large number of solids or particles.

- Longer maintenance intervals

- Slurry Pump

Latest articles

-

Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

-

Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

-

Slurry Pump

-

From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

-

Slurry pipe diameter.

-

- Pumping media where abrasive particles are present

Links

- The lockstitch machine, a pioneering invention in the world of sewing and textiles, has been a cornerstone of industrialization and craftsmanship since its inception. This remarkable device, with its intricate mechanics and unparalleled efficiency, has transformed the way we create, mend, and design fabrics.

3. Versatility Modern industrial overlockers come with a variety of features such as different stitch types, differential feed mechanisms, and adjustable presser feet. This versatility allows manufacturers to handle a range of fabrics, from lightweight knits to heavier materials.

2. Flexibility The chain stitch is highly elastic, which allows the seams to retain their shape even when stretched. This characteristic makes it the preferred choice for sewing knit fabrics or garments that require a degree of stretch, such as athletic wear.

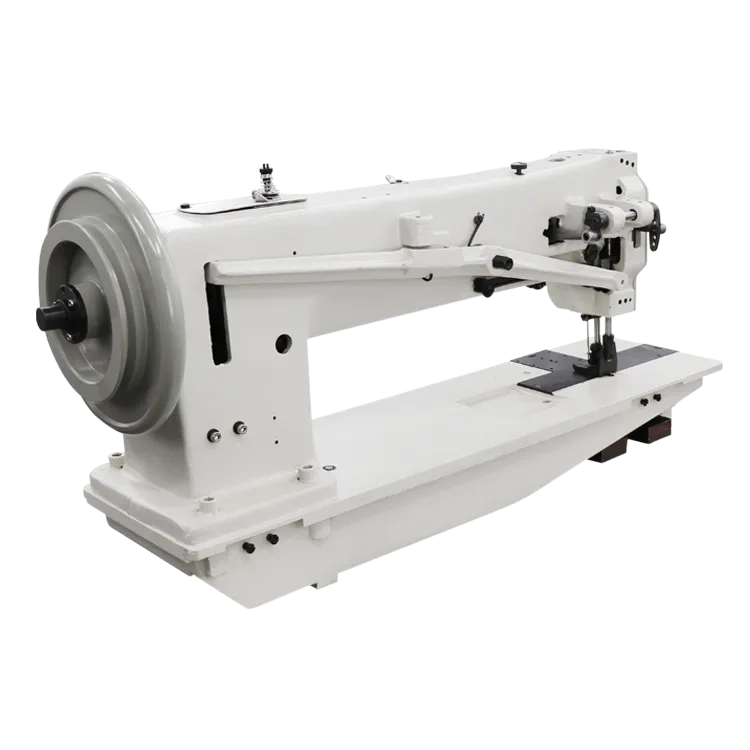

Industrial long arm sewing machines are widely used across several sectors. Some key applications include

4. Included Accessories The price might also reflect the additional accessories provided with the machine. Some models come with various presser feet, extension tables, and needle sets, which can add value to the overall purchase.

Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches

Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches long arm zig zag sewing machine. This versatility makes the long arm zigzag sewing machine a valuable tool for sewers of all skill levels.

long arm zig zag sewing machine. This versatility makes the long arm zigzag sewing machine a valuable tool for sewers of all skill levels.7. Accessories Many computerized sewing machines come with a variety of accessories, such as various feet, a walking foot, and quilting guides. These can enhance your sewing experience and broaden your project options.

what is the best computerized sewing machine to buy

Understanding Cylinder Bed Sewing Machines

Features to Look For

2. Quality The precise stitching capabilities of overlockers ensure that seam edges are neatly finished, minimizing the chances of fabric fraying and enhancing the overall quality of the garment. This is particularly important in a competitive market where consumers expect high-quality products.

In addition to regular cleaning, it’s important to oil your heavy duty sewing machine according to the manufacturer’s instructions. Oiling the machine will help keep the moving parts lubricated and running smoothly. Be sure to use the recommended oil for your specific machine and avoid over-oiling, as this can lead to excess buildup and potential damage.

Environmental and Industry Impact

In addition to hobbyists, the surge in serger machine sales is reflected in the growing professional realm of fashion design. Small businesses and independent designers often turn to sergers for production efficiency without compromising quality. As more people opt for custom clothing and sustainable fashion practices, the demand for sergers in commercial settings is on the rise. This trend is evident at fabric and craft trade shows, where serger machines are frequently showcased with live demonstrations, attracting significant attention from potential buyers.

Understanding the Industrial Chain Stitch Machine A Key Player in Textile Manufacturing

Single needle edge cutter machines are versatile tools used in various applications within the textile industry. They are primarily utilized in the production of garments, where precise edge finishing is crucial for style and durability. From shirts to dresses, trousers to jackets, the machine is indispensable in achieving clean hems and edges.

One of the key advantages of using a double needle coverstitch is its ability to provide a durable seam that won't easily unravel. Unlike standard sewing techniques that can compromise the integrity of the seam when stretched, the coverstitch uses a combination of straight stitching and chain stitching to absorb tension without breaking. This is particularly important in areas of a garment that experience a lot of wear and movement, such as armholes, waistbands, and hems.

A multi-needle quilting machine is designed with multiple needles, allowing the user to stitch various designs and patterns simultaneously. This feature significantly increases productivity, as it enables quilters to create intricate designs without the need to frequently change threads or needles. Most multi-needle machines come equipped with a wide range of built-in designs, fonts, and the capability to import custom patterns, making them versatile tools in any quilter’s arsenal.

Learning to Use the Coverstitch Machine

The Lockstitch Sewing Machine An Essential Tool in the World of Textiles

5. Variety of Stitch Options While straight and zigzag stitches are often sufficient for basic canvas projects, having a variety of stitch options allows for greater creativity and versatility in your sewing projects.

Furthermore, these machines tend to have a relatively small footprint compared to multi-needle or heavy-duty sewing machines, making them ideal for smaller workshops and production facilities. Their user-friendly interface and automatic features also mean that operators can quickly learn to use them, thus reducing training time and increasing workforce productivity.

One of the primary advantages of cylindrical bed sewing machines is their ability to accommodate tubular fabrics effortlessly. The cylindrical shape enables sewers to insert and manipulate fabrics around the machine with ease, making it simpler to work on curved seams and various garment parts. This flexibility not only enhances efficiency but also improves the quality of the finished product, as it minimizes the need for additional handling or adjustments that could lead to errors.

To perfect the single needle top stitching technique, one must consider several essential factors

single needle top stitch

But really, you’re not just making clothing. You’re making memories. Connections. Now seems like a good enough time to start, doesn’t it?

The price of a cylinder bed sewing machine can vary significantly based on several elements, including brand, features, functionality, and the machine's specific purpose. On average, a standard cylinder bed sewing machine can cost anywhere from $1,000 to $5,000. High-end models with advanced features or greater functionality might exceed this range, potentially reaching prices above $10,000.

Conclusion

It’s also important to consider your budget when choosing a heavy duty sewing machine. While these machines are an investment, there are options available at various price points to suit different budgets. Consider the features that are most important to you and prioritize those when making your decision.

4. Cost-Effective Compared to multi-stitch machines with extensive features, single stitch models are often more affordable. For those just starting in leather crafting or who are on a budget, this makes for a practical investment.

single stitch leather sewing machine

The Impact of Price on Single Needle Sewing Machines

Traditionally, sewing leather was done by skilled artisans using hand-operated tools. This method, while effective, was time-consuming and required a high level of expertise. With the advent of industrial sewing machines in the 20th century, the production process underwent a significant transformation. These machines are engineered to handle the unique characteristics of leather, which is heavier and more robust than other fabrics.